6 million tons of municipal solid waste are produced worldwide daily, with the majority ending up in landfills and dumps, contaminating the environment

2 billion tons

of carbon dioxide equivalent are emitted from landfills annually

of all greenhouse gas emissions globally

5%

30 million m³

of garbage is delivered to landfills worldwide daily

could be filled from the bottom to the top in just

Burj Khalifa

2 hours

Traditional recycling technologies have limited capabilities; only 10-15% of waste could be recycled efficiently

20-50%

20-30%

15-20%

10-15%

10-15%

1-10%

0-5%

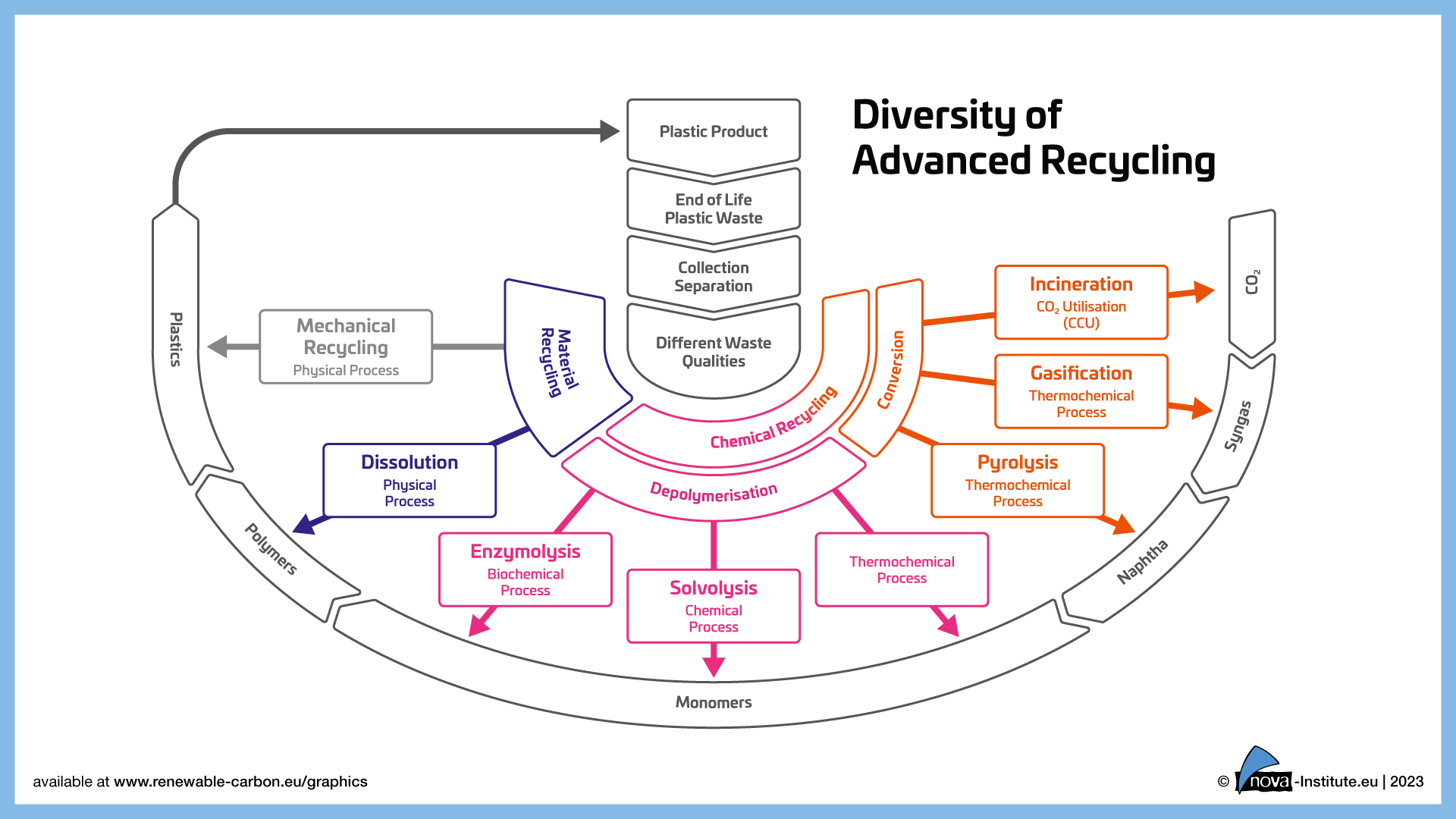

Several advanced recycling technologies are emerging, one of them is gasification

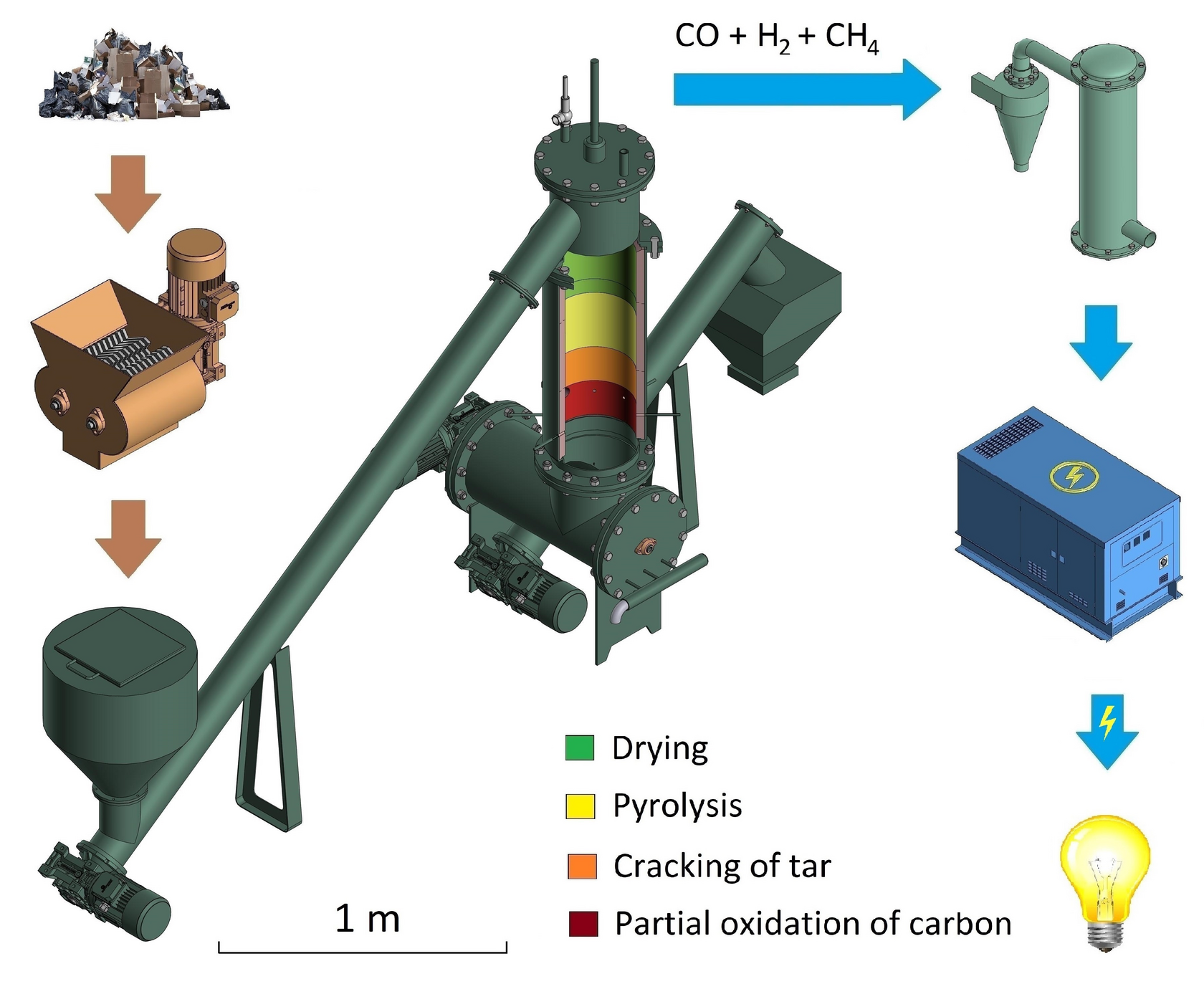

Gasification is a thermo-chemical process of converting carbon-containing waste into synthesis gas and further into electricity or other valuable products

Carbon-containing waste

Valuable products

Our gasification reactor is energy-efficient, compact, and affordable; it is designed for on-site deployment, allowing decentralized waste processing

- No external source of energy is needed

- Utilization of internal energy of waste is high

- ~10% of internal energy to destroy the waste

- Blast air flow is moderate

- Oxidation zone is small and very hot (1200C)

- Hazardous substances are destroyed inside

- Filtration system of outgoing syngas is lean

- Equipment is affordable: $150K+ for a unit

- Unit fits in a 20-foot container

- Waste is utilized locally, no transportation

- Electricity is consumed locally, off-grid

Our prototype can process up to 30 kg of waste per hour, generating up to 20 kilowatts of electric energy, allowing on-site waste processing

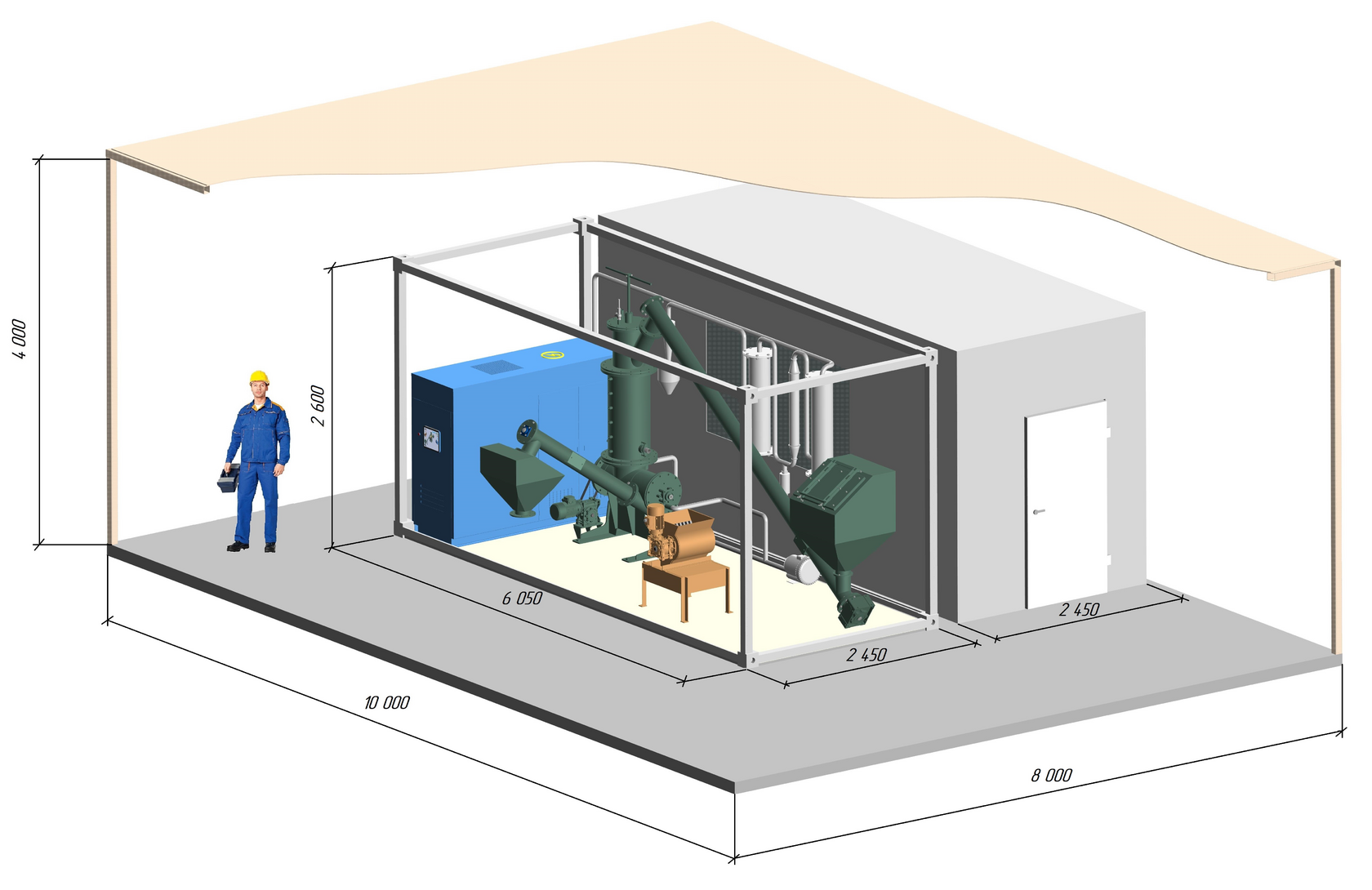

Our commercial unit will process up to 60 kg of waste per hour, generating up to 40 kilowatts of electricity, and will fit into a size of a standard 20-foot container

- Covered outdoor or indoor space: 8*10 = 80 m2

- Shielded space: 3.5*6 = 21 m2

- Air-conditioned space: 2*6 = 12 m2

- Load lifting equipment: up to 2 tons

- Process water, laboratory sink, sewerage

- Fire safety equipment

- Electricity: 15 kW, 220V, and 380V (for the initial R&D phase only)

CleanTainer equipment composition

Required on-site premises

Our target customers are the companies that produce from 100 kilograms to 10 tons of carbon-containing waste per day

- Wood and textile processing companies

- Agriculture farms

- HoReCa in remote locations

- Distribution centers

- Supermarkets in remote locations

- Suburban residences

- Government bodies: army, police, correction facilities

- Auto transportation companies and operators of EOL tires dumps

- Waste processing companies (in the form of partnership)

Without gasification (ton CO2 per ton of waste)

Clients’ waste carbon footprint could be reduced by a factor of five by avoiding methane emissions from dumped waste

With gasification (ton CO2 per ton of waste)

e

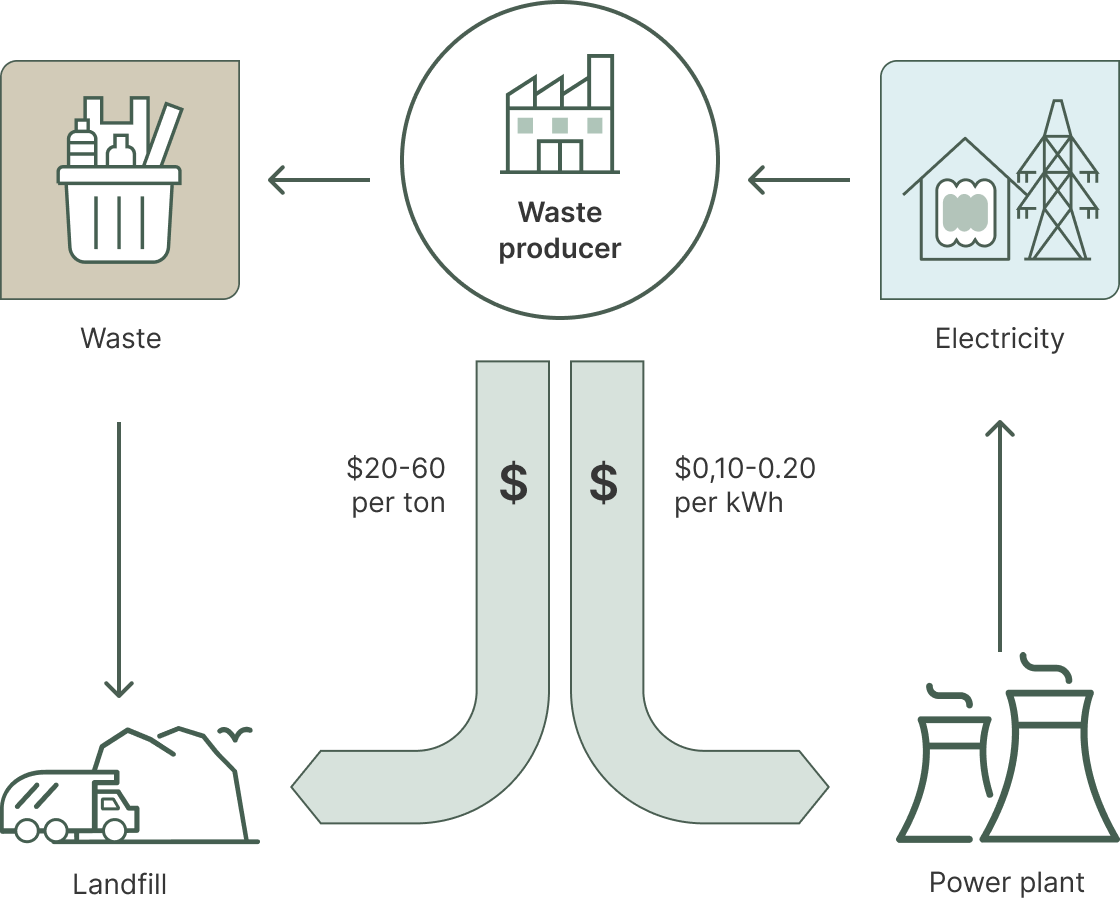

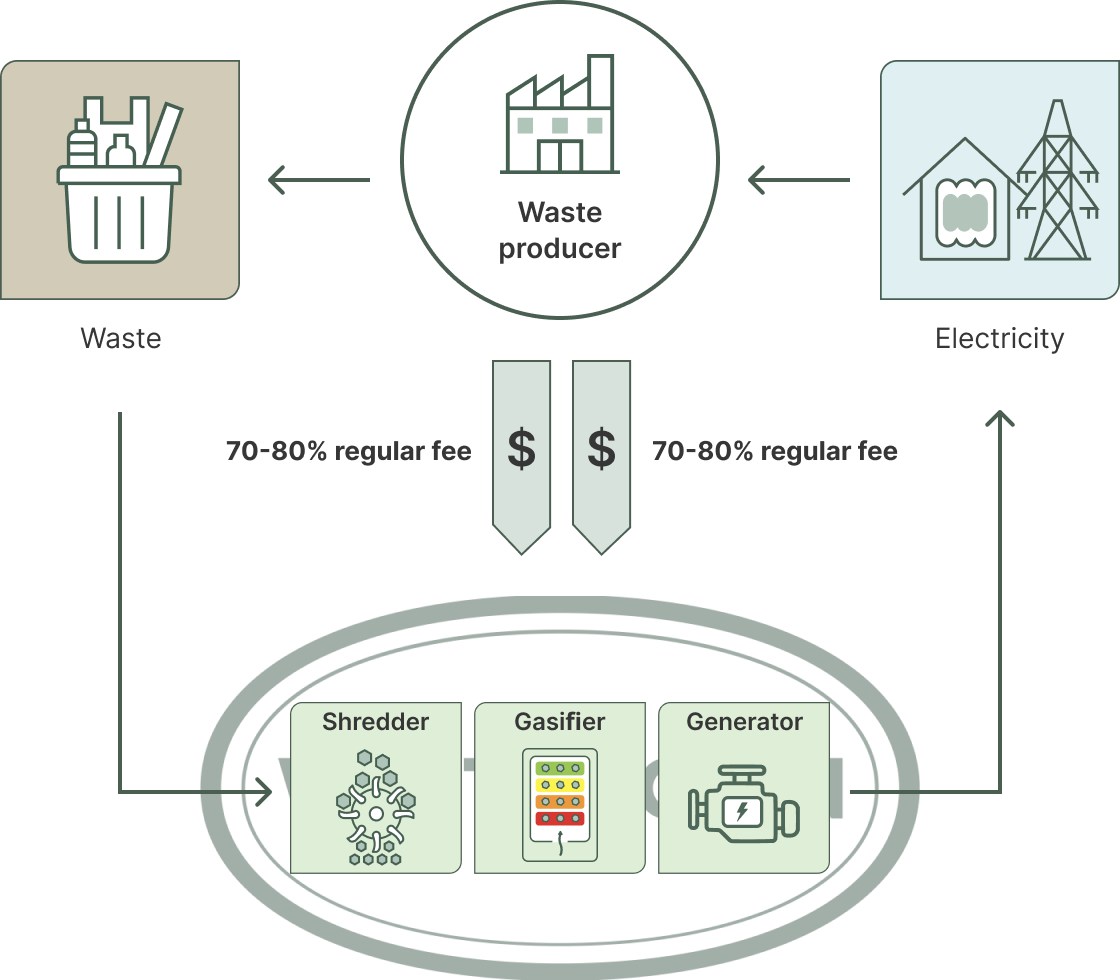

Clients’ waste removal and electricity consumption costs could be reduced by 20-30% by decentralized waste utilization

Without gasification

With gasification

Let’s dump landfills together!

Sergey Likharev, founder and CEO

© 2025 All Rights Reserved. Waste to En

Privacy policy

Privacy policy

Leave a request

We will contact you and answer all your questions

I agree with the privacy policy